Chillers are part of Frigo Plus production program “Smart & Natural Cooling”. The units are used for indirect cooling, which means that the building is cooled with heat transfer fluid. Heat transfer fluid can be water or a mixture of water and ethylene glycol or propylene glycol.

As the unit is intended for indirect cooling, all the components of the refrigerant circuit are built into the unit. Thus, chillers is compact and easy to install on the site. Refrigerant is propane (R290), which due to its excellent thermodynamic properties allows the use of the chiller in the temeprature range from -35 to 20 °C. A microprocessor controls the operation of the unit and optimized parameters in order to achieve as higher efficiency.

Air cooled chillers

Air cooled chillers have air microchannel aluminum condensers paired with axial fans.

Air cooled chillers are divided into 3 subgroups according to the cooling capacity that cover:

- MINI LINE – up to100 kW

- MODULAR – up to 200 kW

- V-LINE – from 100 to 1000 kW

- MINI LINE is the smallest subgroup and only have one compressor. It is suitable for small refrigeration capacities and is characterized by small size, quiet operation, simplicity and reliability.

- MODULAR subgroup is larger in size which allows the installation of special equipment such as an integrated heat exchanger for free cooling, 100% recovery of waste heat and the desuperheater.

- V-LINE subgroup is known for its V design of condenser battery. Wide range of models can cover all the needs of customers. Models with semi-hermetic reciprocating compressors can have up to 4 compressors and models with efficient screw compressors up to 2 compressors. Also, units can have special equipment for the return of waste heat recovery or free cooling module. Advanced microprocessor control automatically manages and controls the unit operation and with the additional equipment it is possible to remote monitor and control the unit operation.

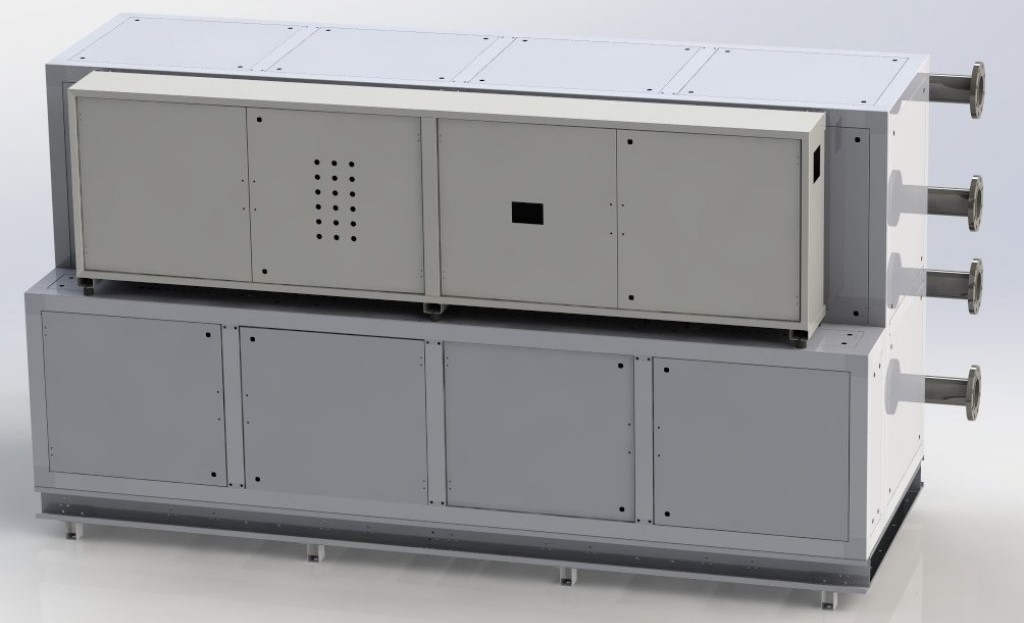

Water cooled chillers

Water cooled chillers have water condensers and simply design, because water condensers are inside the unit. Condensers are plate heat exchangers, with compact size and high heat transfer coefficient. Condensers, as well as evaporators, are connected to a collector which reduces the number of ports on 2 pairs of connections.

Water cooled chillers are intended for indoor installation in the engine room. They cover a wide range of refrigeration capacity, up to 800 kW for standard working conditions. Model of the units can have up to 4 semi-hermetic compressor and a microprocessor controls the operation of devices.